1. Introduction

Overview of Importance and Growth of Footwear Industry

The global footwear market size was estimated at USD 387.74 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030 1. The athletic footwear segment is the largest within the global footwear market and is expected to generate revenue of more than $100 billion by 2025 2. A key driver of growth in the footwear sector is the increasing emphasis on product quality, innovation, and premiumization. Manufacturers are not only developing unique designs but also ensuring a high standard of comfort, which has led to the introduction of innovative products that balance both style and functionality .

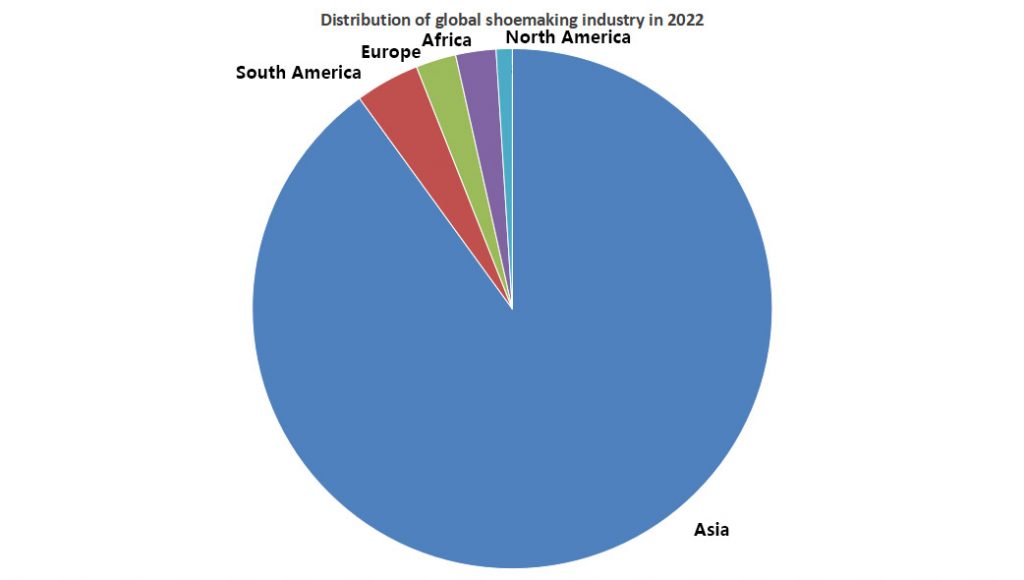

The shoemaking industry is a typical labor-intensive industry. From a global perspective, the production capacity of this industry is always migrating to countries and regions with low labor costs. Historically, the center of gravity of the world’s shoemaking industry has shifted from Italy and Spain to Japan, Taiwan, South Korea, and then to mainland China.

At present, China has become the world’s largest shoe-making center, with shoe production accounting for more than 60% of the world’s total production. However, with the development of China’s economy and the rise in labor costs, the shoemaking industry has a tendency to move to countries with cheaper labor, such as Vietnam, India, and Pakistan.

However, from the perspective of quality, most customers still firmly choose Chinese shoe factories. The stable production supply chain and high-quality shoes have established China’s position as the largest shoe-making country.

From 2015 to 2022, both the global footwear industry’s output and demand showed a fluctuating upward trend. In 2018, the global footwear industry market output reached 27.176 billion pairs, and the demand reached 26.518 billion pairs. However, due to the impact of the market environment in 2019, production and demand declined compared with the previous year, reaching 24.279 billion pairs and 22.155 billion pairs respectively.

| Nation | Main shoe production base |

| China | Hangzhou, Wenzhou, Heshan, Dongguan, Foshan, Jinjiang, Qingdao, Chengdu, Chongqing, Hong Kong |

| India | Tamilnadu, Mumbai, Agora, Kamppur, Delhei, Garandhara |

| Mexico | Lyon, Guadalajara |

| Vietnam | Ho Chi Minh City |

| Spain | Valencia, Castile-La Mancha |

| Italy | Lombardy, Vigneto, Marche, Emilia-Romagna, Tuscany, Camponia and Bogoria |

| Thailand | Bangor Cork |

| South Korea | Sign Mountain |

| Brazil | Shinos Shoe Valley |

2. The importance of understanding the manufacturing process

A. How understanding the manufacturing process increases consumer appreciation

B. Consumers desire to understand the drivers of manufacturing processes

C. Benefits of Transparency in the Footwear Industry

A: Understanding the manufacturing process of shoes can increase consumer appreciation because it allows consumers to better understand the skill, craftsmanship and effort that goes into making a pair of shoes. It allows them to feel the quality and value of the product they are purchasing. Additionally, it allows consumers to make more informed decisions about the shoes they purchase as they can evaluate factors such as sustainability, ethical practices and materials used in the manufacturing process.

B. Consumer awareness of the footwear manufacturing process is driven by growing consumer interest in sustainability and ethical practices. Many consumers are concerned about the impact of the fashion industry on the environment and want to ensure that the shoes they purchase are produced in a responsible manner. By understanding what drives the shoemaking process, consumers can choose brands and products that align with their values, such as those that prioritize fair labor practices, use environmentally friendly materials, or have transparent supply chains.

C. Transparency in the shoe industry brings several benefits. First, it empowers consumers to make more ethical and sustainable choices by providing information about the manufacturing process, including the origins of materials and the working conditions of factory employees. This transparency fosters trust between brands and consumers. Second, transparency can help identify and address any potential issues or concerns, such as labor abuses or environmental impacts. This will improve industry practice and promote accountability. Finally, as consumers increasingly look for companies that align with their values, transparency can create a competitive advantage for brands that prioritize ethical and sustainable manufacturing processes.

3. Introduction to leading shoe factories

Brief history and establishment of the factory

MYWAY shoes factory is a leading manufacturer of Private Label Shoes and offers OEM&ODM services in World. We have leveraged advanced technology and an efficient supply chain to aid world-renowned footwear brands in producing exceptional shoes. With a workforce of 200 skilled professionals and 8 production lines, we manufacture 7 million pairs of shoes annually. We maintain long-term business relationships with well-known companies such as BATA, ALDI, and LIDL. Further, our factory is spread over 8 thousand square miles and accredited with certifications like ICS, BSCI, and SEDEX.

As a responsible business, we believe in respecting human rights and our planet. At MYWAY, we realize that our commitments are in the hands of individuals who hold the power to effect meaningful change. We partner with innovators, advocates of peace, change makers, and families. We possess sourcing expertise that enables us to discover cutting-edge, sustainable materials such as bio-based, vegan, nature-grown, organic, recycled waste outsoles, and low carbon emission options. Preserving our environment is a priority for us, and we prioritize nature over profit. We are committed to a regenerative and restorative fashion business that supports a circular economy.

4.A step-by-step breakdown of the manufacturing process

A. Design and Prototyping

1. The Importance of Innovative Design and Trends

2. Create prototypes for testing and evaluation

B. Material Procurement and Preparation

1. Different types of raw materials used

2. Procurement practices and quality control measures

C. Cutting and shaping

1. The role of advanced machinery in precision cutting

2. Shape the material into different parts of the footwear

D. Assembly and sewing

1. Creation of upper and sole components

2. Use modern technology to sew and connect components

E. Durability and finishing

1. Formation of the final shape of the footwear

2. Finishing work and quality inspection

5. Sustainability and ethical practices

A. Sustainable sourcing and production initiatives

B. Implement ethical labor practices

C. The relevance of sustainability and ethics to the modern consumer

6.Quality control and assurance measures

A. Strict quality control procedures

B. The Importance of Quality Assurance in the Footwear Industry

C. Comply with international standards and certifications